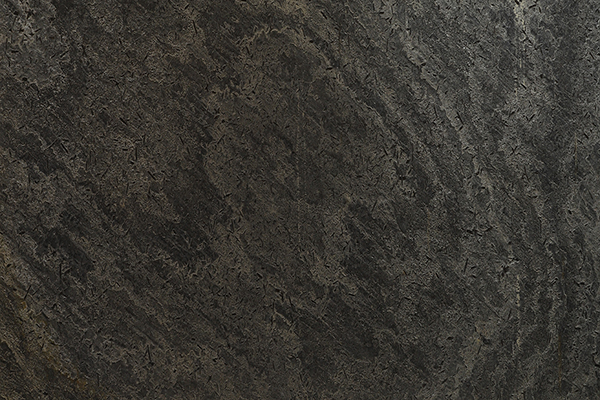

Rocks Studio is the largest manufacturers, suppliers and exporters of Tumbled River Wash Granite in Ahmedabad, India. Tumbled River Wash Granite, as its name suggests, is magnificent white granite with a wave-like structure of grey and brown colour. This granite originates from Brazil, and it is in high demand all around the world. The offered range of Tumbled River Wash Granite has a gleaming polished surface and a silky smooth feel. It has a lovely colour and texture to it. The presence of grey waves running across its gorgeous white surface makes this stone the first pick of all. Because of the advantages it provides, this granite is becoming a popular choice among homeowners. Tumbled River Wash Granite is known for its durability and ease of maintenance. It is an excellent flooring product that comes highly recommended by architects. This granite is used for indoor floors, countertop, and wall decorating. If you’re searching for light granite that will warm up your kitchen, look no further. Because Tumbled River Wash Granite is a natural stone, no chemical processing is required; just surface polishing is required. We also offer customized solutions as per the various requirements of the customer at affordable prices.